Superalloy Castings From RapidProtoCasting®

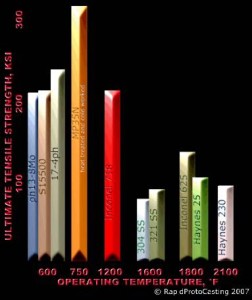

RapidProtoCasting maintains a stock of commonly specified high-strength high-temperature medical and aerospace super alloys for immediate use including nickel alloys, cobalt chromium alloys, nickel cobalt alloys, precipitation hardening stainless steels, 300 series stainless steels, 400 series stainless steels and titanium alloys.

AUSTENTIC STAINLESS STEEL CASTINGS

Type 304 stainless steel castings

Type 304 stainless steel (18% chromium, 10% nickel) is the most commonly used stainless steel for fabricated, stamped, machined and cast stainless steel parts.

Type 304L stainless steel castings

Type 304L stainless steel is the low carbon version of type 304 stainless steel and is widely used for medical castings, castings operating in high-temperature corrosive environments and applications where as-welded castings are used without post-weld heat treatment. A metal may be specified as 304/304L if it meets the low carbon chemistry requirements of 304L stainless steel and the higher strength requirements of Type 304 stainless steel.

Type 316 stainless steel castings

Type 316 stainless steel (18% chromium, 14% nickel) is the second most commonly specified metal for stainless steel castings after type 304 castings. The addition of molybdenum and higher nickel content provide greater corrosion resistance.

Type 316L stainless steel castings

Type 316L stainless steel is the low carbon version of type 316 stainless steel. It is used for medical instrument castings and implant castings and is widely used for castings operating in marine environments where the lower carbon level reduces intergranular corrosion. A metal may be specified as 3164/316L if it meets the low carbon chemistry requirements of 316L stainless steel and the higher strength requirements of Type 316 stainless steel.

Type 321 stainless steel castings

Type 321 stainless steel (18% chromium, 10% nickel) is suitable for higher temperature service than either type 304 or type 316 stainless steel with the addition of 0.7% titanium to reduce chromium carbide precipitation above 800°F (426°C).

MARTENSITIC PRECIPITATION/AGE-HARDENING STAINLESS STEEL CASTINGS

13-8 stainless steel castings (ph13-8Mo)

13-8 stainless steel (13% chromium, 8% nickel) provides excellent casting strength, toughness, corrosion resistance and resistance to stress-corrosion cracking. 13-8 stainless steel castings can be heat treated to 195 ksi (1344 MPa) UTS and is one of the strongest cast alloys available at reasonable cost.

15-5 stainless steel castings

15-5 stainless steel (15% chromium, 5% nickel) is used in casting applications where lower tensile strength is required compared to 17-4 stainless steel and higher toughness is desired compared to 13-8 and 17-4 stainless steel castings.

17-4 stainless steel castings (17-4ph)

17-4 stainless steel (17% chromium, 4% nickel) is widely used for medical instrument castings, aircraft engine castings and industrial casting applications where high-strength, high hardness and excellent corrosion resistance are required.

INCONEL CASTINGS

Inconel 625 castings

Inconel 625 (21% chromium, 58% nickel) alloys provides castings with superior resistance to high temperature corrosion and stress-corrosion cracking at service temperatures up 1800°F (982°C). It is the lowest cost alloy available for high-temperature casting service.

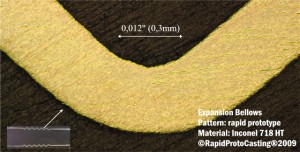

Inconel 718 castings

Inconel 718 (19% chromium, 52% nickel) alloys provides castings with excellent high temperature strength, toughness, corrosion resistance and resistance to stress-corrosion cracking at service temperatures up to 1300°F (704°C).