Unique Titanium Shell System From RPC

Zero Continuous Alpha Case As-Cast

RPC’s unique titanium primecoat and backup shell dips deliver a unique composition and method for producing shells for investment casting of titanium alloys. The RPC titanium investment system eliminates continuous alpha case formation on as-cast surfaces and reduces trapped air when casting parts with complex 3D shapes and small features. Thin layers of intermittent alpha case on as-cast parts enables rapid prototyping of titanium castings without additional development work to assess as-cast alpha case thicknesses and overstock new patterns or post-process machining to remove overstock and achieve specification dimensions.

- Zero continuous alpha case.

- Exceptional pattern coverage without special processing.

- 12 hours wax assembly to furnace.

- Thin primecoat reduces high-cost refractory usage.

- Thin backup dips deliver exceptional strength.

- Excellent as-cast surface finish.

- Reduced surface defects.

Demonstrated Titanium Casting Alpha Case Reduction

RapidProtoCasting’s unique titanium facecoat and backup dips delivers as-cast Ti6-4 parts with zero continuous surface alpha case and intermittent alpha case less than 0.003″ thick intersecting the untreated as-cast surface. Compared to conventional investment casting shell systems, RapidProtoCasting’s proprietary investment casting technologies deliver:

- Reduced surface defects and improved surface finish.

- Improved dimensional stability and reduced casting distortion.

- Reduced metal mold interaction, surface contamination and titanium alpha case.

- Reduced process time, queue time and WIP.

- Eliminates caustic shell removal and reduced chem mill requirements.

- Reduced environmental management and waste disposal costs.

- Casting capabilities allowing access to new markets.

- Process capabilities for new and emerging cast materials.

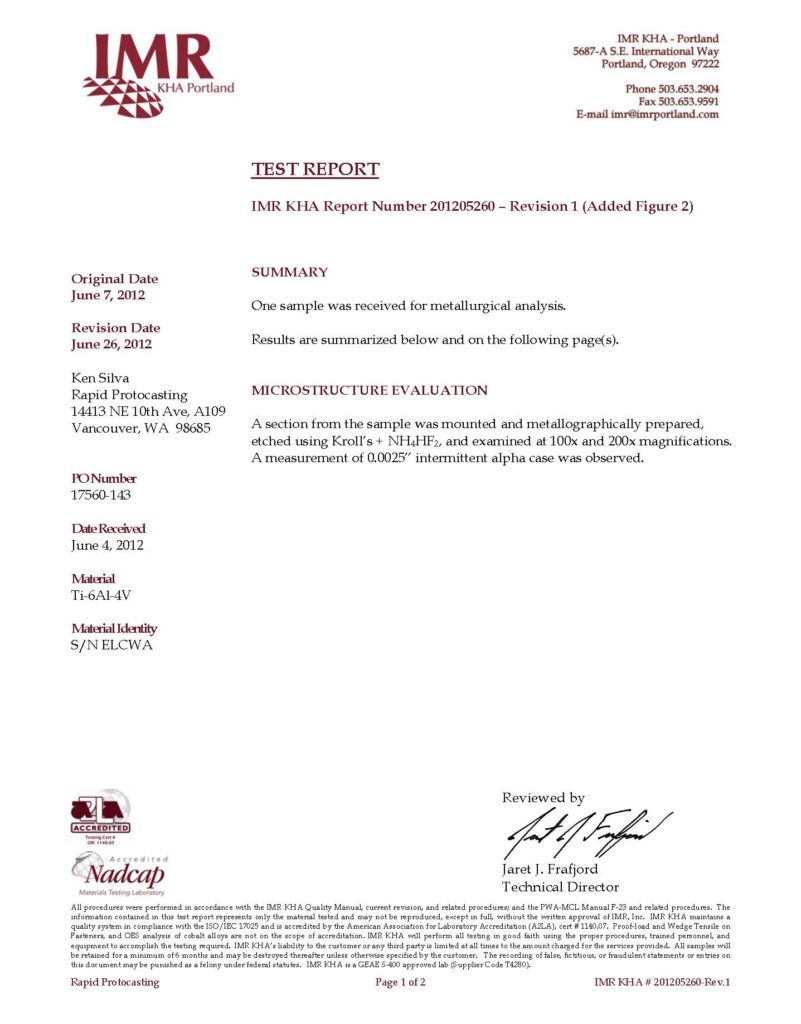

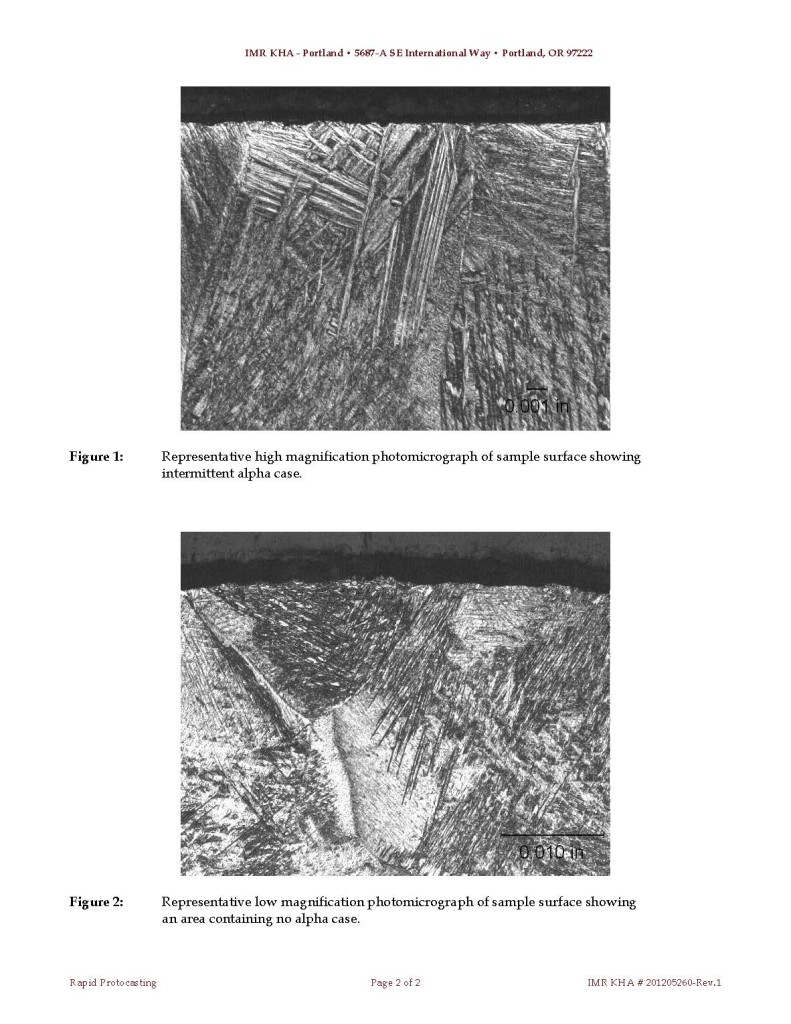

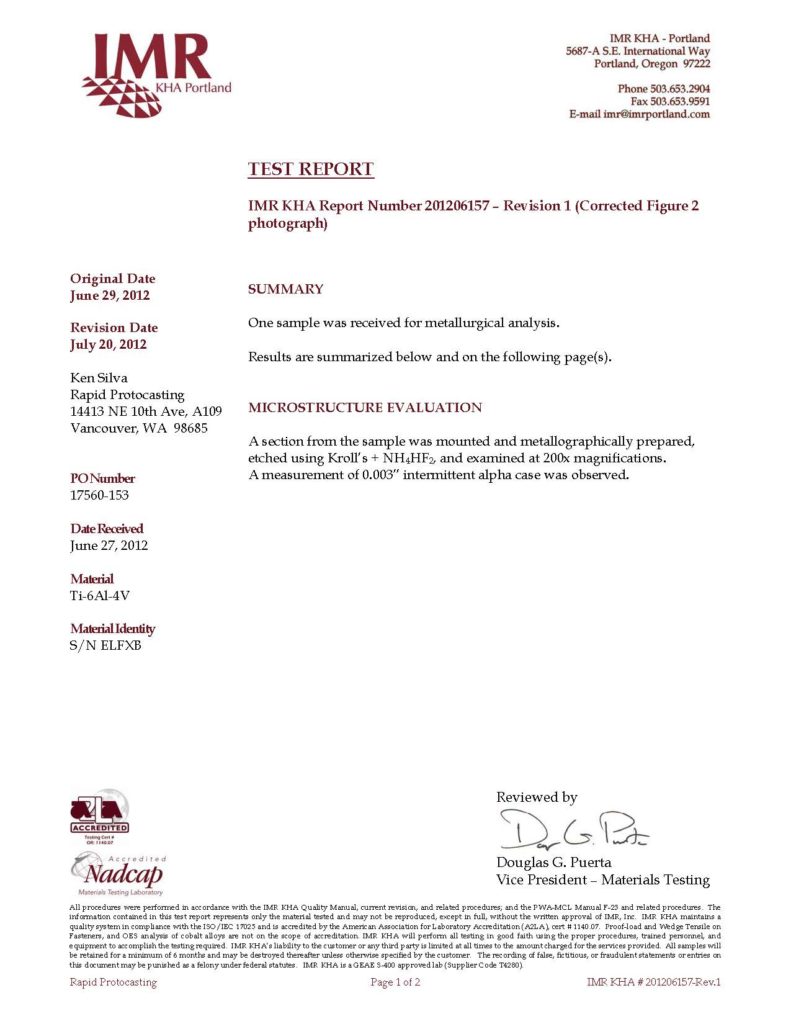

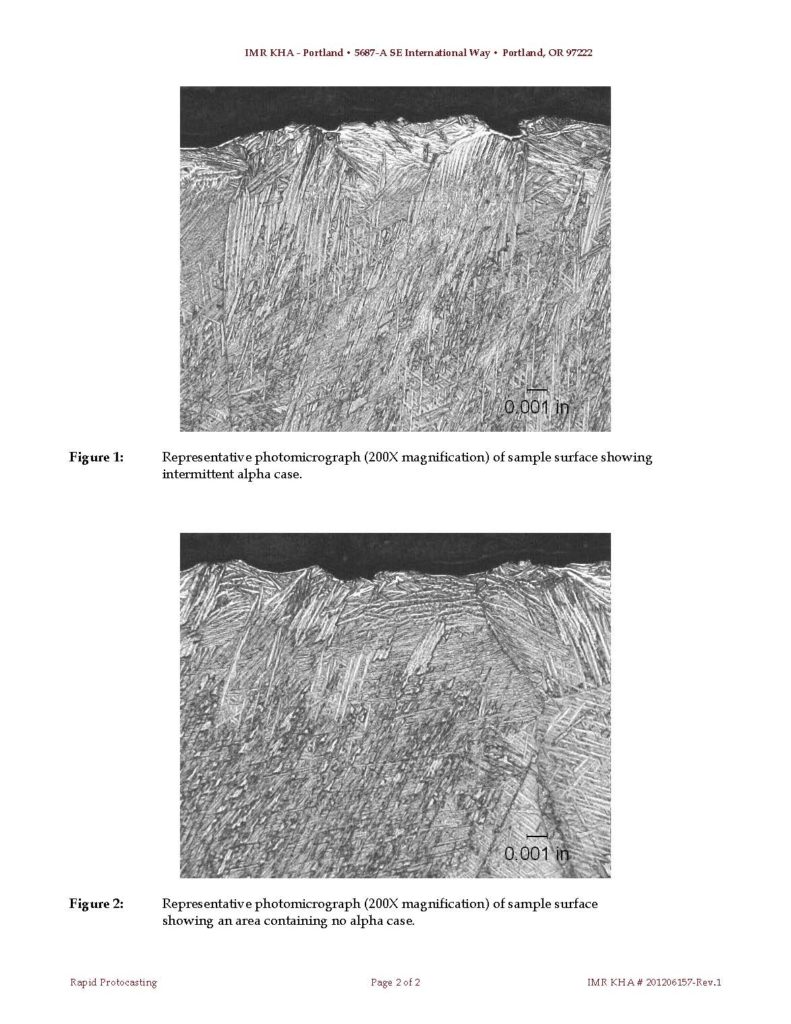

Laboratory Tested As-Cast Ti6-4 Alpha Case Less Than 0.003″ Intermittent

RapidProtoCasting’s Ti6-4 as-cast parts were submitted to IMR KHA-Portland for alpha case evaluations of complete casting cross-sections. Results are shown in the two reports to the right- click on the snapshots for a full-size pageview. IMR KHA in Portland, OR is a Nadcap, A2LA, ISO 17025 and GE S-400 Accredited Testing Laboratory.