Finishing and Inspecting Precision Castings at RapidProtoCasting®

RapidProtoCasting® combines product engineering, rapid prototyping, lost-wax investment casting, induction-melt vacuum casting and casting inspection services to deliver rapid manufacturing of engineered prototype metal parts.

POST PROCESSING

Castings can be machined, ground, drilled, reamed, EDMed, threaded, plated and polished where net shape castings are not possible or where close tolerances cannot be achieved during casting. Casting mechanical properties can be adjusted by heat treating to increase tensile strength to more than 250ksi and hardnesses exceeding 45 Rc. Casting surface roughness can be increased or decreased from a nominal 32-65 micro-inch/Ra (0.8-1.6 micro-m/Rz) as-cast and casting surfaces can be treated to increase wear resistance when the as-cast or heat treated cast metal properties are not sufficient.

INSPECTION

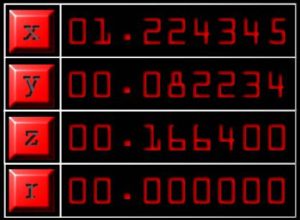

Castings are 100% visually inspected, sample castings are sectioned for integrity and metallographic evaluation, and

casting critical dimensions are gage or non-contact vision system inspected to 0.00005″ (0.001mm). Certified metrology, casting metallography, ultrasonic inspection, radiographic inspection and liquid penetrant inspection can be performed to ASTM, AMS, ANSI or special customer specifications.