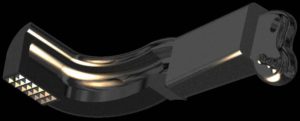

Sketch to CAD to RP to Finished Casting: RapidProtoCasting is your one stop shop for casting development.

RapidProtoCasting® Rapid Manufacturing of Prototype Investment Castings

RapidProtoCasting combines product engineering, rapid prototyping, low-wax investment, induction-melt vacuum casting and inspection services to deliver rapid manufactuirng of engineered protype metal parts.

ENGINEERING

RapidProtoCasting works from your engineered component solid model to produce high-strength, dimensionally accurate finished castings. Starting with .igs, .stp, .dwg, parasolid or .stl files, RapidProtoCasting> modifies the files to create rapid prototypes or plastic patterns for use in our lost-wax investment casting process. RapidProtoCasting can also work from 2D drawings or sketches to create a 3D model for customer review and casting development.

RAPID PROTOTYPES

RapidProtoCasting has in-house rapid prototype capability and we work with rapid prototype service bureaus to create precision rapid prototypes for prototype and low volume castings. Rapid prototypes are fully inspected and measured to ensure the necessary casting quality and dimensions.

WAX AND PLASTIC PATTERNS

RapidProtoCasting> works with toolmakers and plastic injection companies to produce precision plastic patterns for low-volume and moderate-volume castings, typically 50 to 5000 parts. Plastic injected patterns enable surface finishes of 32 micro-inches/Ra (0.8 micro-m/Rz) and dimensional variation down to + 0.002″

(0.05mm). Part designs that cannot be tooled (injected in one piece) can be injected as multiple parts and assembled to meet part surface finish and dimensional requirements.

LOST WAX INVESTMENT CASTING

RapidProtoCasting embeds the rapid prototype or plastic patterns in high-temperature industrial refractories. High temperature industrial furnaces cure the refractory materials, producing a ceramic mold that precisely replicates fine detail, thin sections, undercuts, radii and lettering. High-strength medical and aerospace alloys are vacuum induction melted and poured into the ceramic molds producing a dense dimensional casting often requiring little finishing or post-processing

POST PROCESSING

Castings can be machined, ground, drilled, reamed, EDMed, threaded, plated and polished where net shape castings are not possible or where close tolerances cannot be achieved during casting. Mechanical properties can be adjusted by heat treating to increase tensile strength to more than 250ksi and hardnesses exceeding 45 Rc. Surface roughness can be increased or decreased from a nominal 32-65 micro-inch/Ra (0.8-1.6 micro-m/Rz) as-cast and surfaces can be treated to increase wear resistance when the as-cast or heat treated base metal properties are not sufficient.

INSPECTION

Castings are 100% visually inspected, sample castings are sectioned for integrity and metallographic evaluation, and critical dimensions are gage or non-contact vision system inspected to 0.00005″ (0.001mm). Certified metrology, metallography, ultrasonic inspection, radiographic inspection and liquid penetrant inspection can be performed to ASTM, AMS, ANSI or special customer specifications.