Inconel Castings From RapidProtoCasting®

The name Inconel® refers to a family of nickel chromium metal alloys used for their high strength, corrosion resistance and wide temperature capability. Corrosion protection is provided by high levels of chromium and molybdenum. High temperature strength is provided by high levels of grain boundary precipitate hardeners including titanium, columbium (niobium), tantalum and aluminum.

Inconel investment castings are fabricated by vacuum induction melting (VIM) barstock followed by hot isostatic pressing (HIP) and age-hardening heat treatment. Inconel alloys possess excellent welding characteristics if required to repair casting defects or for in-service repairs.

INCONEL 625 CASTINGS

are regularly used in saltwater, aerospace and chemical processing applications. Inconel 625 castings provide excellent resistance to seawater and chloride stress corrosion cracking. Inconel 625 castings contain a relatively high level of molybdenum which provides excellent high temperature strength up to approximately 1800°F (982°C) including high fatigue strength and high creep strength. Inconel 625 castings can be welded without pre or post heat treatment. Inconel 625 is also known as CW6MC, 60Ni-22Cr-9Mo-3.5Cb and UNS N26625.

INCONEL 713C CASTINGS

are typically used for high-temperature, high-speed aerospace castings including jet engine gas turbine blades and smaller jet engine blisks. Inconel 713C Castings provide outstanding resistance to thermal fatigue and exceptional rupture strength at 1700°F (927°C). Inconel 713C is also known as Ni-13Cr-6Al-4Mo-2Cb-0.7Ti, Allvac 713, Austenal 655, Esco 713C-E, CAPI-371, Udimet 713C, Haynes Alloy No. 713C, Vertex 713C and ASTM UNS N07713.

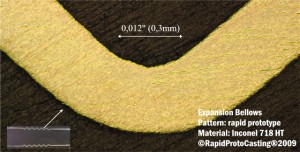

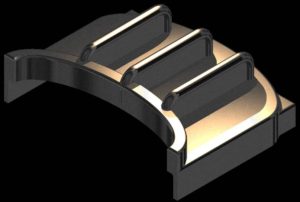

INCONEL 718 CASTINGS

are typically used for jet engine castings, high-speed airframe castings, land-based gas turbine castings, oil field castings, rocket motor castings, spacecraft, nuclear reactor component castings, pumps and castings for cryogenic applications. Inconel 718 is a precipitation-hardenable nickel-chromium alloy containing relatively high amounts of iron, niobium, and molybdenum along with smaller quantities of aluminum and titanium. Inconel 718 castings provide excellent corrosion resistance and high strength. Inconel 718 castings can be easily welded and are resistant to postweld cracking. The alloy has excellent creep-rupture strength at temperatures up to 1300°F (700°C). Inconel 718 is also known as UNS 07718, UNS N07718, Udimet 718, Allvac 718, Pyromet Alloy 718 and Haynes Alloy No. 718.

Inconel is a registered trademark of Special Metals Corporation