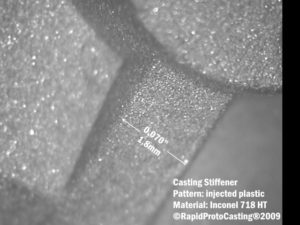

Metal Prototypes From RapidProtoCasting®

Precision superalloy prototype castings of complex engineered designs from RapidProtoCasting

PROTOTYPE MODELS

RapidProtoCasting specializes in quick delivery of one to fifty castings within days using customer supplied or service bureau rapid prototype patterns. Test different casting designs for market research, functional testing, production testing and medical trials. RapidProtoCasting express casting processes combine the latest rapid prototyping, vacuum induction melt investment casting, test and inspection technologies to deliver high-quality metal prototypes.

METAL RAPID PROTOTYPES

Quick and flexible processes get your 3D CAD model off the screen, onto your production line and into your customer’s hands. Four weeks low-cost, low-volume production of precision complex superalloy castings for clinical trials, testing, trade show samples, market introduction, early production and mass customization.

BRIDGE PRODUCTION

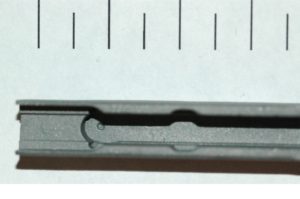

Castings in machined, MIM or stamped configurations enable accurate testing of production designs and speeds Design for Six Sigma and Design For Manufacturing to maximize production outsourcing flexibility.

QUICK MANUFACTURING

RapidProtoCasting can deliver precision castings from in-stock alloys in as short as one day after receipt of a rapid prototype pattern and as little as four days after receipt of a CAD solid model. Functional prototype castings, mechanical metal prototypes, conceptual metal models, medical prototypes, low-volume castings and bridge production castings up to 500 parts/week can be provided in as little as four weeks.

HIGH STRENGTH PROTOTYPE CASTINGS

RapidProtoCasting melts and pours medical and aerospace alloys providing high mechanical strength, excellent high temperature creep resistance, good corrosion and oxidation resistance, high temperature phase stability and high hardness. Typical applications include:

- Gas Turbine Engine Prototypes for hot gas path and fuel system components.

- Prototype Aerospace Castings for aircraft engines, high temperature fuel systems and unmanned aerial vehicles.

- Medical Device Prototypes including endoscopic and laproscopic end effectors, surgical instruments and orthopedic implants.

- Prototyping Industrial Castings requiring complex precision engineered designs for fixtures and end-products.

FUNCTIONAL PROTOTYPES

RapidProtoCasting full-function cast prototypes can be developed to exceed the strength, surface finish and dimensional specifications of production parts. RapidProtoCasting prototypes meet or exceed the properties of FDM or SLS rapid prototypes, CNC prototypes and sheet metal prototyping and are often delivered faster and at lower cost.